|

|

| Wheels & Tires for 1985-1987 Turbo Regals |

|

Greg Wentz

gwentz@rt66.com |

| "THE TIRE SOME DETAILS" |

The majority of information presented in this page was re-printed with permission from The TURBO BUICK NEWSLETTER (TBN), published and edited by Daryl Riegel. The information presented below is intended to help one gain a basic understanding of wheel and tire techno-babble so that you might make a wiser decision when replacing your OEM wheels and tires.

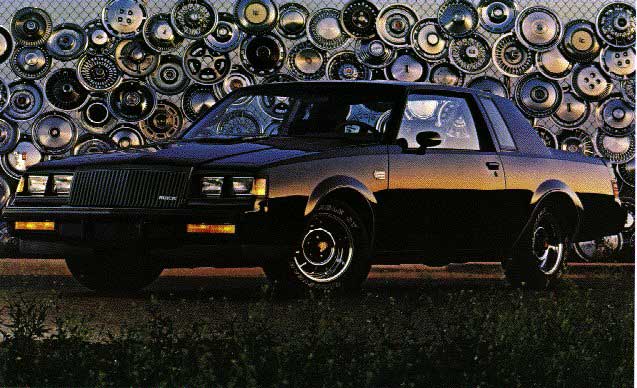

The way it was...

Turbo Regals with the exception of GNXs were factory equipped with P215/65R15 Goodyear Eagle GTs. These tires were non-speed-rated and were NOT all-season radials. White letter Goodyear GTs of the same size were an option. The tires were mounted on either chrome-plated steel wheels ('86/'87 GN) or ribbed aluminum wheels ('84/85 GN, '86 T-Type & '87 Turbo-T). There were other wheels available for other turbo-packaged Regals but these are the two most common styles. Both styles were 15"x7". '86/'87 GN wheels had a 3mm negative offset and 4" of rear backspacing. The aluminum wheels had 3 3/4" of rear backspacing. The circle bolt pattern was 5 X 4 3/4 inches.

Grand National -------

------- T-Type

T-Type

The GNXs came with P245/50VR16 Goodyear Gatorbacks on the front and P255/50VR16 on the rear. They were black letter, NOT all-season, and mounted on 16'x8" modular style wheels with a black center section and polished rims. The front had a 15mm positive offset and the rear, a 23mm positive.

Tire Nomenclature

Currently there are several classifications and designations of tires. To be knowledgeble about tires, you must be familiar and understand what all of the markings mean. This is the only way to achieve the right match of tire and rim.

There are at least four systems used to identify tires:

P-METRIC

Code Schemes: W/ASCD LS & W/ACD LS Example: 215/65HR 85H 215/65R 85H W - Tire section width (millimeters) (ex: 215 mm) A - Aspect ratio (percentage) (ex: 65%) C - Construction (ex: R - radial) D - Diameter (inches) (ex: 15 inches) L - Load index (see chart) (ex: 85) S - Speed rating (see chart) (ex: H)

NUMERIC SYSTEM

Code Scheme: W-D Example: 8.25-15 W - Tire section width (inches) (ex: 8.25 inches) D - Diameter - Rim (inches) (ex: 15 inches)

W - The tire section width is the total width of the tire including sidewall bulge. Do not confuse this with tread width. The tread width (footprint/contact patch) is significantly less. NOTE: The section width increases .2 inches for every .5 inch increase in rim width. Please be sure to compensate for this in ALL your computations. A - The aspect ratio is a percentage of the tire section width (W) that makes up the tire's heigth. If the width were 215mm and the aspect ratio were 65, the tire section heigth (sidewall) would be (65% of 215) or 139.75mm. C - The construction is of type: R: Radial ply B: Bias-belted D: Diagonal or Bias ply LS - The service description consists of a load index (L) and a speed rating (S) which is further explained below. L - The load index ranges from 0 to 279. Passenger car tires usually range from 75 to 100. Divide the Gross Axle Weight Rating (GAWR) by two. It's usually on a sticker located on the side of the driver's door (GAWR-FRT front) and (GAWR-RR rear). For example, a front of 2169 and a rear of 2278 equates to 84 & 86 (minimum) respectively (2169 divided by 2 and 2278 divided by 2).

Load Index - - Load lbs./wheel- - GAWR

S - Speed ratings (S) range fron A1 (3mph) to Z (149+mph). Passenger car tires maximum speed ratings are as follows: P - 94 mph U - 124 mph Q - 100 mph H - 130 mph R - 106 mph V - 130+ mph (w/o load indexes) S - 112 mph V - 149 mph (w/load indexes) T - 118 mph Z - 149+ mph (by manufacturer)

Speed rated tires usually can be repaired and retain their speed rating, although H, V, & Z rated may only have one .25 inch puncture. Any more, and the tire cannot retain the orginal speed rating.

Older tires, without speed ratings such as stock GOODYEAR EAGLE GT 215/65R15 have a rating of less than 113 mph. This is interesting since the stock computer chips allow turbo-Buicks to acheive 124-128 mph. The stock tires are considered "safe" because no-one usually maintains these speeds for any length of time. (The rating is based on a ten minute period.)

Max Load & Max Inflation

P-Metric system tires have a load range:

P - passenger (standard) usually 4-ply (35 psi)

XL - Extra load 6-ply (41-44 psi)

Alpha-Numeric and Numeric system tires use different load ranges.

B - standard 4-ply (32 psi)

C - extra load (36 psi)

D - extra load (41 psi)

LT - light truck

Ply Information

There is ply information on the tire which shows type of construction.

ex:Tread Plies: 2 Polyester + Steel + 2 Nylon

Sidewall Plies: 2 Polyester

UTQGL - Uniform Tire Quality Grade Labeling

Treadwear

The higher the rating, the longer the projected tread life under optimal conditions. Driving style, road conditions, alignment, rotation, and other factors can affect a tire's life expectancy. For comparison purposes, the index is a percentage grading based on 100 being average. The treadwear is rated against other tires from THE SAME manufacturer. For example, a treadware rating of 150 from company X means that tire will wear 1 & 1/2 times as well as a tire from that company with a rating of 100 given the driving conditions are constant. As another example, B.F. GOODRICH Radial T/A HR4 has a rating of 310 and B.F. GOODRICH Comp T/A HR4 Has a rating of 340. The Comp T/A HR4 should last 1.096 times as long as the Radial T/A. The actual tread-wear warranty is a more easily digestible figure that indicates the number of miles a consumer could expect from a properly maintained tire. Many tires carry a 40,000 mile warranty, which translates to an index of approximately 360.

Traction

The traction index rates STRAIGHT-LINE stopping ability on wet concrete and asphalt surfaces using the A, B, and C scale, with A being the (best) and C the (worst). Purchase decisions shouldn't be based strictly on this rating, as it doesn't take into account handling on other surfaces such as dry or snow covered pavement, nor does it rate cornering and acceleration abilities.

Temperature Rating

A rating of the tire's ability to dissipate and resist heat, on a scale of (from highest to lowest) A, B, and C. To earn the highest grade of "A", a tire must withstand a half hour run at 115 mph without failing. Like treadwear and traction index ratings, the temperature index can only be used to accurately compare within a manufacture's product line. All passenger tires must achieve a rating of C. A & B represent higher levels of performance than are required by law.

All-Season

M/S, M+S, or M&S states the tire meets the Rubber Manufacture's Association (RMA) definition for mud and snow. Current trends are the use of a "4" in the tire model's name.

NOTE: Stock GOODYEAR Eagle GTs are NOT all-season tires!

Radial Construction

They must state "RADIAL" on the tire. Radial ply construction tires comprise the vast majority of the passenger-car market.

TPC Spec

The TPC spec states the tire has met the General Motors performance specifications.

Tubeless

They must state "TUBELESS" or "TUBETYPE".

Department of Transportation

DOT XXXX XXX - "DOT" means the tire meets the Department of Transportation safety standards. The code identifies the tire manufacturer, plant, type of tire construction, and date the tire was made. The last three numbers indicate the week and the last digit of the year the tire was made.

Wheel & Tire Formulas

NOTE: Each tire's section width is based on a particular rim size and construction. Compensate for differences. Increase section width .2 inches for every .5 inch increase in rim width. For example, if the tire's section width is 9.14" on a 6.5" rim and is to be mounted on a 7" rim, the section width would be 9.34". Section width (sidewall flex) will vary by construction. ANY variance will affect calculations!

Radius - Diameter - Circumference

To compute the diameter of a P-Metric tire, multiply the section width by the aspect ratio (as a percentage). If necessary, divide this number by 25.4 to convert millimeters to inches. For example, a 215/65 equates to a tire height of 5.5019685 inches (215 x .65) divided by 25.4. Multiplying this by 2 for the top and bottom sidewall height and adding the rim size will get the overall tire diameter. For example, if the tire is on a 15 inch rim, it is approximately 26 inches ((5.5 x 2) + 15). The radius is half of the diameter. Multiplying the diameter by pi (3.1415927...) will get the circumference.

Tire Revolutions Per Mile

To compute the number of tire revolutions per mile, divide 20,168 by the diameter.

20168

-------------------------------------- = Tire Revs/Mile

(Tire Heigth X 2) + Rim Size

For a 215/65R15:

20168

---------------------- = 775

(5.5" X 2) + 15

For a 255/60R15:

20168

------------------- = 747

(6" X 2) + 15

Speed

By dividing the original tire revolutions by the new tire revolutions and multiplying by the indicated speed on the speedometer, we arrive at the new actual speed.

(Orig. Tire Revs/Mile) ------------------------------- X Indicated Speed = Actual Speed (New Tire Revs/Mile) Using the above tire sizes: (775) -------- X 60 mph = 62 mph (747)

Rear Axle Ratio

Changing tire diameters will also change the effective rear axle gear ratio. Divide the new tire revolutions by the original tire revolutions and multiply by the original axle ratio. For example, a turbo Buick that had 215/65s and a rear axle ratio of 3.42 (what else?) and moved to a 255/60 will net an effective ratio of 3.30.

(New Tire Revs/Mile) ---------------------------- X Orig. Axle Ratio = Effect. Axle Ratio (Orig.Tire Revs/Mile) (747) -------- X 3.42 ratio = 3.30 ratio (775) As you can see, this will theoretically raise the top speed of the vehicle but hurt its acceleration. To regain the original effective ratio with the new tires, a 3.55 ratio is required. (Orig.Tire Revs/Mile) ------------------------------ X Orig. Axle Ratio = Equiv. Axle Ratio (New Tire Revs/Mile) (775) --------- X 3.42 ratio = 3.55 ratio (747)

Maximum Speed

To calculate the maximum speed of a vehicle, take:

Overall Tire Diameter X Achieved Engine RPM (redline)

----------------------------------------------------------------------------- = Max Speed

Differential Ratio X Top Gear Ratio X 336

26" X 5250

--------------------------- = 177 mph

3.42 X 0.67 X 336

This differs from actual speed. A stock turbo-Buick's actual top speed is in the

152 to 162 mph range. The aerodynamics on these cars are nothing to write home

about.

Lateral Acceleration

To measure lateral acceleration (cornering ability), use:

1.227 X R

g = -----------

(T X T)

R is the radius of the turning circle and T is the time (in seconds) required for

one lap. Stock turbo-Buicks usually can achieve .79 to .80g.

Tire Mixing

It is always best to have all four tires the same size and construction. If mixing is necessary, install radials on the rear and non-radial on the front and/or wider tires on the rear than front. Never mix constructions and/or sizes on the same axle.

"Plus One / Plus Two Sizing Concept"

This allows vehicles to use lower aspect ratio (lower profile) tires by increasing wheel rim diameter (+1/+2 inches), rim width, and tread width to gain handling and traction. Choose larger diameter tire which retains revs/mile and load capacity.

Rim Width Recommendations

Where ranges are specified, V & H speed rated tires require and can accomodate a wider rim. Check with specific manufacturer!

50-Series

(P)195/50xR15 5.5 - 7.5"

(P)205/50xR15 5.5/6.0 - 8.0"

225/50xR15 6.5 - 9.0"

P245/50xR15 6.5 - 9.5"

P265/50xR15 7.0/7.5 - 10.0-10.5"

P275/50xR15 7.0 - 11.0"

* P285/50xR15 7.5 - 11.0"

P295/50xR15 7.5 - 11.0-11.5"

* P295/50xR15 8.0 - 11.5"

60-Series

195/60xR15 5.0 - 7.5"

205/60xR15 5.5 - 8.0"

215/60xR15 5.5 - 8.5"

225/60xR15 6.0 - 9.0"

* 225/60xR15 6.0 - 8.0"

(P)235/60xR15 6.0 - 9.0"

*(P)235/60xR15 6.0 - 8.0"

P245/60xR15 6.5 - 9.5"

(P)255/60xR15 6.5 - 10.0"

*(P)255/60xR15 6.5 - 9.0"

*(P)265/60xR15 7.0 - 10.0"

P275/60xR15 7.0 - 11.0"

65-Series

215/65xR15 5.5 - 8.0"

(P)- same for passenger and non-passenger tires

/ - denotes manufacturer model construction variance

* - denotes tire designation conversion estimates computed

from the Tire and Rim Association Inc.

NOTE:Within a rim range, a middle width should be used for normal driving

and a wider rim width should be used if improved handling is preferred.

Additional information can be found using the following links:

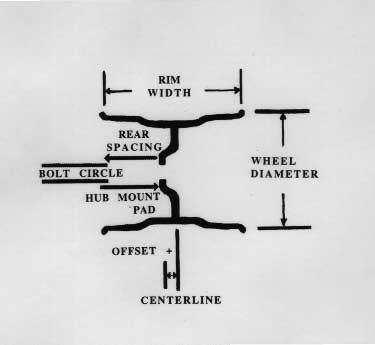

UNDERSTANDING WHEEL TERMINOLOGY

The following is a list of defined terms which need to be understood before aftermarket wheels can be intelligently purchased.

RIM WIDTH - The distance between bead mounts (where the tire attaches to the rim)

CENTERLINE - Half of the rim width (center)

OFFSET - The distance from the centerline to the hub mount pad (where the wheel attaches to the hub)

POSITIVE OFFSET - Centerline is outside of hub mounting pad (increases vehicle track)

NEGATIVE OFFSET - Centerline is inside of hub mounting pad (decreases vehicle track)

Note: Using wheels with greater negative offset than stock can increase strain on wheel bearings and spindles. Inspect more frequently. Be sure to check clearance with frame and inner fender UNDER CORNERING SITUATIONS!

REAR SPACING / REAR BACKSPACING / BACKSPACING

The distance from the inner edge of the wheel to the hub mount pad

Note: Sometimes the distance from the outer edge of the wheel to the hub mount pad is referred erroneously to as offset. BE CAREFUL!

BOLT PATTERN:

- Number of lugs

- Bolt Circle - The diameter of the imaginary circle which intersects the centers of the lug holes.

GENERAL WHEEL FACTS

Look for the lighest weight wheel (least unsprung weight requiring least energy to get them moving) yet having the strength required by your type of driving. Brake cooling fins are a plus.

Steel:(sheet metal rolled rim welded to a stamped center)

Pluses: inexpensive, very strong, many sizes & offsets

Minuses: heavy, not much lateral (cornering) support

Aluminum:(usually light alloy)

Pluses: fairly light, fairly strong, improves handling, fairly inexpensive

Minuses: can crack or break them more easily than steel, fewer sizes and offsets than steel

Cast:

Low-pressure: inexpensive, more prone to damage

High-pressure: more strength

High-counter-pressure: more expensive, more strength

Rolled,Stamped: common

Forged: ultimate strength

Magnesium: (aluminum with some magnesium)

Pluses: very light

Minuses: Corrodes easily and requires constant care, expensive, not recommended for everyday driving

Usually the more pieces (1,2,3-piece) there are to a wheel, the greater its strength and price. One piece wheels accept wider tires for improved traction and handling.

BALANCING

There are three ways to balance a wheel: static (bubble), dynamic (spin) and on the car spin. Bubble balancing is an older method. Spin balancing is done with a machine which electronically marks the wheel for balancing. On-the-car spinning is the most precise because the car spins the wheel while mounted and a strobe light marks the wheel for balancing. The weight of the brake drum and rotor is included.

Last updated: